Coburg North, Melbourne — Serving All of Victoria

A noisy commercial exhaust fan in Melbourne is rarely “just old”. Noise is usually feedback: vibration, turbulence, pressure mismatch, or a system being forced to run at one speed for every moment of the day.

This guide helps you identify the type of noise, find the real cause, and choose fixes that work — before it becomes a staff comfort issue or a neighbour complaint.

Fix: inspection + clean + balance. Imbalance accelerates bearing wear and makes everything louder over time.

Fix: replace isolation mounts and use flexible connections where appropriate to stop structure-borne noise.

Fix: re-secure, check curb integrity, and re-tension fixings.

Fix: improve transitions and avoid abrupt changes that create turbulent “roar”.

Fix: re-route or space bends where possible to stabilise airflow.

Fix: resize duct or re-spec the system so you’re not forcing excessive velocity (which sounds like a jet engine).

Fix: clean/replace filters and then reassess noise at peak load.

Fix: install a VSD controller so the fan runs to demand, not maximum all day.

Fix: review discharge point and rooftop behaviour. In many sites, directing discharge upward helps reduce recirculation and turbulence. See vertical discharge fans.

Fix: address make-up air so the exhaust fan isn’t “fighting the building”. If noise changes when doors open, this is a strong clue.

Fix: replace bearings/motor before failure (and before the vibration damages mounts and duct supports).

Fix: add supports/stiffening, adjust routing, and isolate vibration transfer points.

| Symptom | Likely cause | Fast check | Typical fix |

|---|---|---|---|

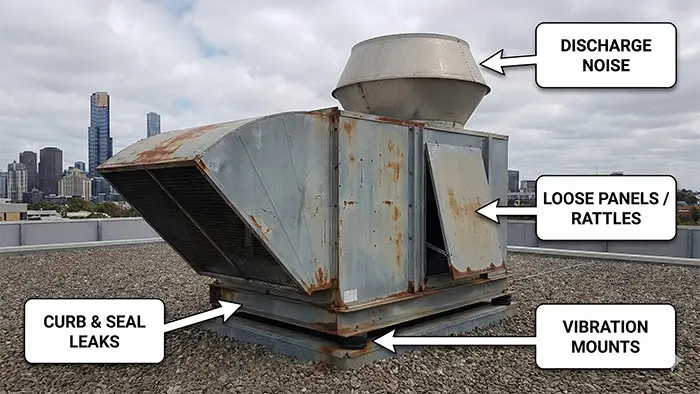

| Rumble + roof shaking | Isolation/mount failure | Feel vibration at curb | Replace mounts, add flex |

| Roar at high speed | Restriction/turbulence | Listen near transitions | Improve duct transitions |

| Pulsing / surging | Pressure mismatch/backdraft | Changes with doors open | Re-spec fan/discharge, address make-up air |

| Rattle | Loose panels/cowl | Tap panels, check screws | Tighten/secure components |

| Noise increases over weeks | Filters loading / grease build-up | Check filter and impeller condition | Clean/replace and reassess |

Repair if the noise is caused by mounts, loose parts, dirty impeller, or a simple imbalance and the motor/bearings are still healthy.

Replace/upgrade if the fan can’t hold performance against real duct resistance, the system needs speed control for noise/cost, or the discharge setup is wrong for the site.

If your rooftop fan is driving staff mad or complaints are starting, don’t guess. Send a short rooftop video and a rough duct sketch and we’ll identify likely causes and the cleanest fix path.

Request a quote/inspection and see how we handle installation and manufacturing.

Common causes include filters loading up, grease build-up on the impeller creating imbalance, or mounts loosening over time.

Yes. Noise often rises sharply with fan speed. A VSD controller lets you run lower during light load and ramp up only when needed.

That’s a strong clue the kitchen is too negative (make-up air imbalance) or the system is surging as pressure changes.

Start with isolation mounts and structural fixings, then check impeller cleanliness and balance.

They can be, depending on rooftop conditions and discharge behaviour. They often help by directing discharge upward and reducing turbulence and recirculation near rooflines. See vertical discharge fans.